Premium Enamel Handmade in Austria

There are up to 40 work steps behind every product made of RIESS premium enamel. Each piece is carefully made by hand and is an original.

Hohlgriff - Entlüftungsloch

Dieses befindet sich auf der Rückseite unserer Hohlgriffe oder an geschlossenen Bördelrändern. Es dient dazu, dass die Luft entweichen kann, die sich durch die Hitze des Brennvorgangs ausdehnt.

“Seam” on the inside of the hollow handle

Riess products have two to three layers of enamel (depending on the model): base enamel and colored top enamel.

Because the base enamel separates easily during firing, a thin line called a “seam” is created inside the hollow handles where the sides meet.

Long Hollow Handel - open Rim

On the back of the long handles for pouring pots, cooking pots, etc., the edges are left open around the hanging hole and where the handle is welded to the pot. The iron remains visible here.

The supporting points

This is where the hook is attached to the rolled rim of the enamel cookware, to hang up the cookware to dry and/or afterwards for firing. A small dot remains here, as the enamel cannot adhere to it.

Open rim - narrow

When “edging” (= milling the forms), a rim develops where the porcelain enamel cannot be fused with the iron. A black line appears where the iron remains visible. Our ladles are an example of this.

Open rim - wide

For products made of thick iron (aromapot, goose roasting dish), the

profile of the mill remains visible at the open rim after the edge is

created. The porcelain enamel cannot be bonded with the iron here

either.

The feet remain visible on the porcelain enamel under the rim. Here, the pots are placed on rails to dry.

Rolled rim - open

The rim of the blank is curved downwards and around to prevent any sharp edges. Once the porcelain enamel has been applied, the carrier material, iron, remains visible on the underside because the porcelain enamel cannot adhere to the narrow edge. Evenly shaped rolled rims are a real craft in enamelling.

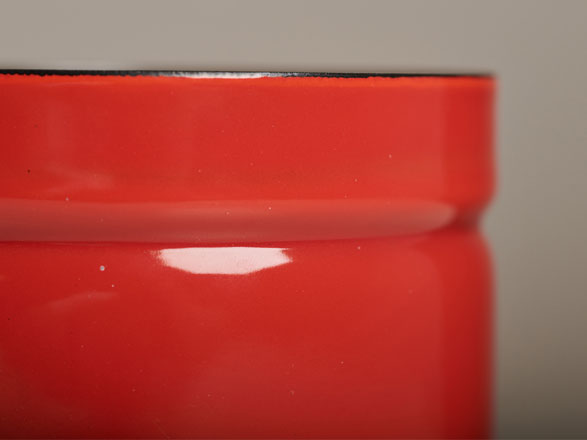

Rolled rim - closed

A few products (e.g. drinking vessels) have the rolled rim completely curved inwards and closed. Technical ventilation holes are required to allow the hot air to escape during the firing process. These are visible as small black dots.

Protective metal rim

Many of our cooking pots have a protective rim made of metal to provide protection to this exposed part. This is attached after the porcelain enamel is applied. The ends of the metal rim remain visible.

The Riess seal

The hand-applied seal is located at the bottom of each product. Riess proves that this is an original RIESS product - of premium quality and hand-made in Austria. This makes the piece a genuine RIESS product.